Injection Moulds Manufacturer in Delhi | Cretech Moulds

Precision-Engineered Injection Moulds for Every Industry

Since 2013, Cretech Moulds has been a leading Injection Mould Manufacturer in Delhi, specializing in designing and producing high-precision, durable, and efficient injection moulds for industrial applications. With advanced technology and expert craftsmanship, we deliver moulds that meet the highest standards of performance, reliability, and accuracy.

Our custom-designed injection moulds are used across various sectors, including automotive, packaging, electrical, and consumer goods, helping manufacturers achieve consistent product quality and optimized production output.

Our Expertise in Injection Mould Manufacturing

At Cretech Moulds, we combine cutting-edge technology with skilled engineering to design injection moulds that meet exact specifications and exceed expectations. We specialize in:

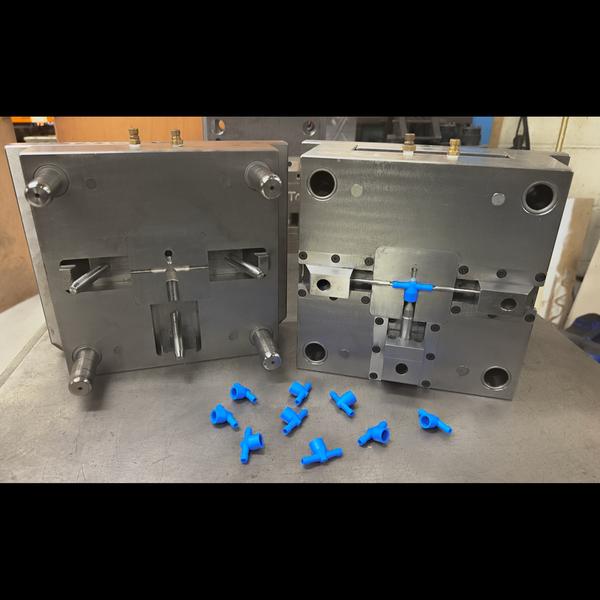

- Single cavity & multi-cavity injection moulds

- Prototype and production moulds

- High-speed precision moulds

- Insert and over-moulds

- Custom-designed moulds for complex geometries

Every mould is crafted using premium-quality materials, ensuring dimensional accuracy, longer tool life, and seamless moulding performance.

Industries We Serve

Our injection moulds are trusted by clients across multiple industries:

- Automotive Components

- Consumer Products

- Packaging and Containers

- Electrical & Electronics

- Construction and Industrial Parts

- Medical & Healthcare Devices

From small precision components to large industrial parts, Cretech Moulds delivers moulds that perform flawlessly in high-volume production.

Key Features of Our Injection Moulds

- High dimensional stability and repeatability

- Durable, corrosion-resistant materials

- Smooth surface finish and precision detailing

- Optimized cooling channels for faster cycles

- Compatible with standard and custom injection moulding machines

- Low maintenance and long operational life

Our Design & Manufacturing Process

- Concept & CAD Design – We use advanced CAD/CAM and 3D modeling for accurate mould design.

- Tool Engineering – Our engineers optimize every detail for strength and efficiency.

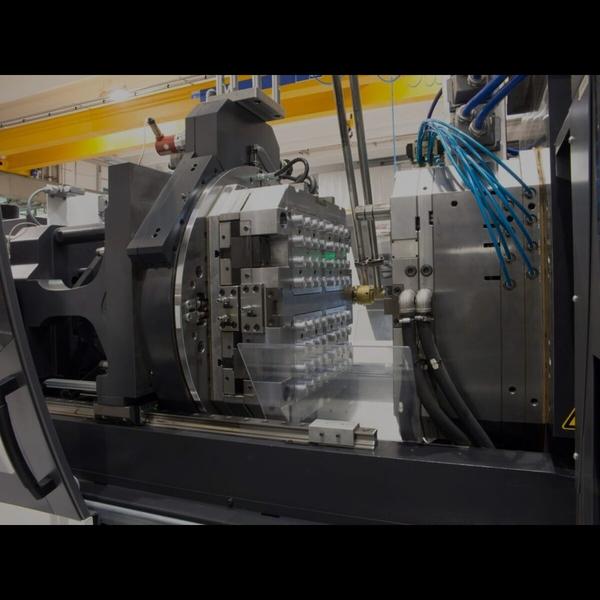

- Machining & Fabrication – CNC and EDM machining ensure precision and consistency.

- Testing & Validation – Each mould undergoes trial runs and inspection for quality assurance.

- Delivery & Support – On-time delivery with after-sales service and technical support.

Why Choose Cretech Moulds?

✅ Over 10 Years of Experience – Proven expertise since 2013.

✅ Custom Design Solutions – Moulds tailored to your exact product and production needs.

✅ Modern Infrastructure – Equipped with CNC, EDM, and advanced design software.

✅ Stringent Quality Control – Every mould tested to ensure accuracy and durability.

✅ Competitive Pricing & Timely Delivery – Reliable service that fits your timeline and budget.

Applications of Injection Moulds

Our injection moulds are used to produce:

- Automotive interior and exterior components

- Electrical housings and switchgear parts

- Packaging containers, caps, and closures

- Plastic handles, enclosures, and fittings

- Household and consumer plastic products

Quality Assurance

Quality drives everything we do at Cretech Moulds. From material selection to final delivery, each mould is thoroughly inspected to ensure it meets client specifications and global quality standards. We focus on precision, durability, and consistent performance in every project.

Contact Us for Injection Moulds in Delhi

Looking for a trusted Injection Mould Manufacturer in Delhi?

Get in touch with Cretech Moulds for customized, high-performance mould solutions that enhance productivity and product quality.

📞 Phone: 1808 048 036479

📧 Email: info@cretechmoulds.com

🌐 Website: https://www.cretechmoulds.com